Our ServiceConsistent Craftsmanship

From the planning of the design concept and products through manufacture, our comprehensive internal process guarantees our customers high quality and speedy OEM / ODM.

The process, from the first meeting to the final delivery

-

1.Request

-

2.PlanningMarket research, Concept definition, Materials collection, Design

-

3.DiscussionConcept confirmation, Materials selection, Discussion on design, function and image colors

-

4.DesignOriginal pattern development, Materials discussion, Prototype, Fitting check

-

5.PresentationExplanation of concept and function, Information of materials, Comparing silhouettes, Disclosure of related data and color pallet

-

6.OrderMaterial arranging, Quality cheking, Pattern making, Size developing, Specifications of arranging manufacturing capacity

-

7.Material procurementLabo dip(for color matching), Quality Inspection

-

8.ManufacturingMaterial control, Pattern control, Sewing and quality control with consistent management at our own factories

-

9.Inspection / DeliveryDelivery to designted places

Design proposal

We listen to the customerʼs requests sincerely and propose the best design.

Material proposal

We work with a wide range of material manufactures, so we propose the most suitable material for any customer’s request.

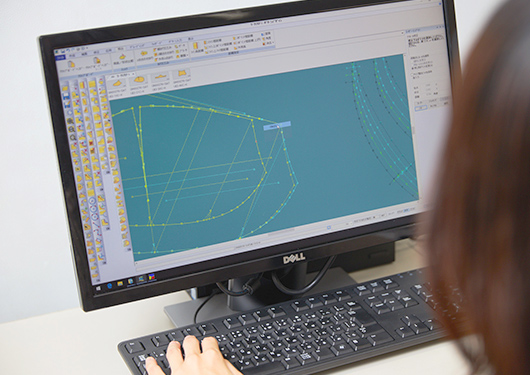

Pattern Grading

We develop to the other sizes prototype size patterns.

Color check

According to the customer’s specifications, we check the color matching of material and sewing thread in our lightbox.

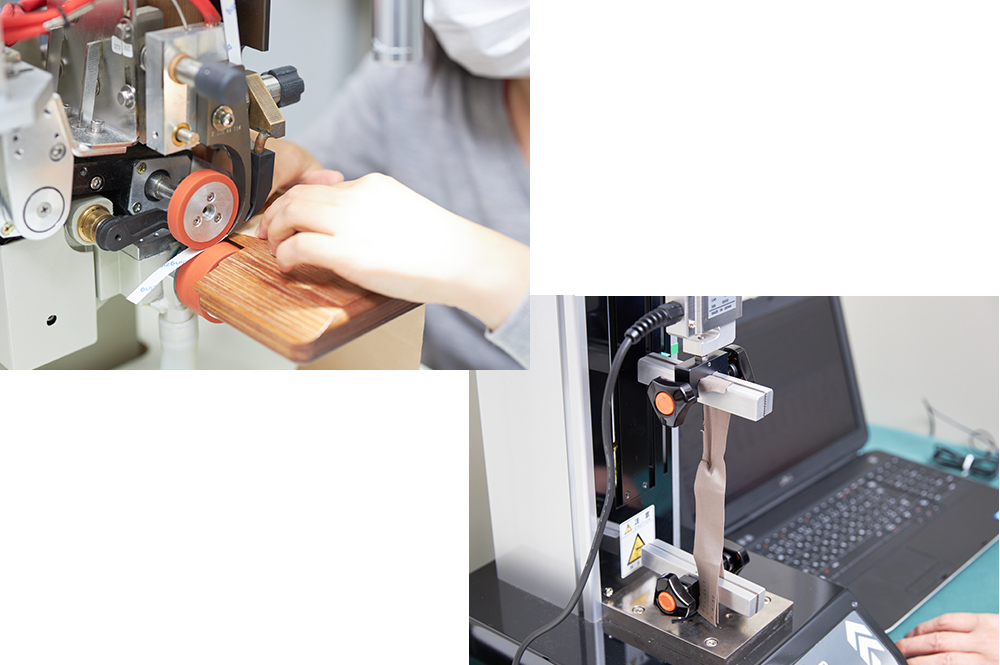

Thermal adhesion

The adhesive equipment that is used in the production factory is also available in the sample making room at the head office. We make samples and verify the strength thoroughly.

Processing of sewing machine attachments

We make original presser feet and binders in-house and address complicated sewing specifications.